Your Essential Guide to Laser Cut Woodworking and Engraving

This article is written to be your best guide to laser cut woodworking and engraving without facing the common issues that most people go through during wood laser cutting.

- The Problems of Laser Cut Woodworking

- Do Laser Cut Woodworking Like a Pro

- Wrapping up

The Problems of Laser Cut Woodworking

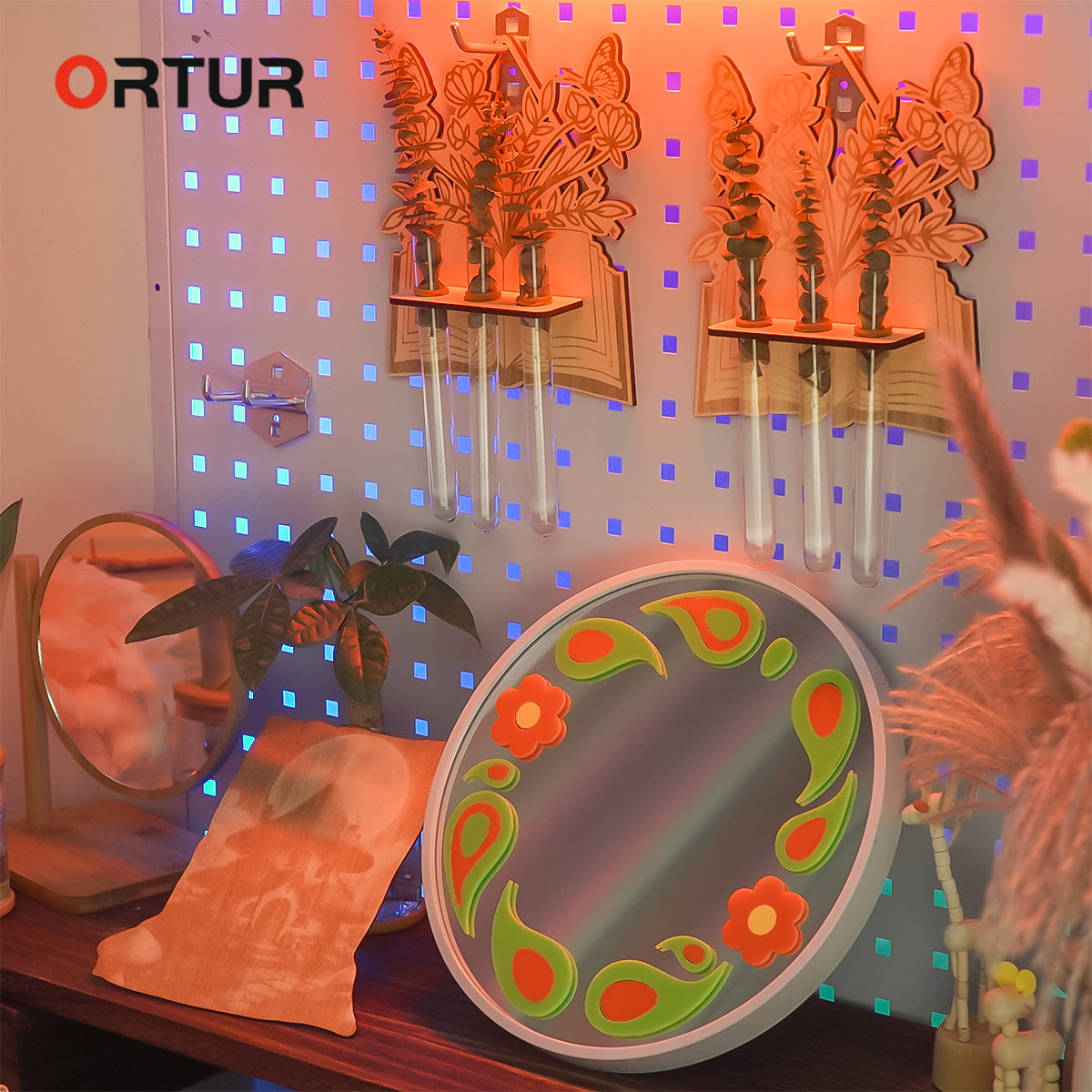

After plastics, wood is the second most used material for DIY projects because of its versatility and wide variety of personal and industrial applications. It can be cut, sanded, shaped, and finished into nearly infinite designs, offering high aesthetic value. Wood can be laser cut for precise engraving, those small signboards and displays at the coffee shops near your house are all laser engraved. This technique is also used in home décor and personalized wooden gifts.

Although wood laser cutting and engraving is great and frequently used, it can also go through common problems such as burning wood, inconsistency in the cuts, potential fire hazards, resin buildup, and even smoke and fumes. This happens due to inconsistent kerf width, material thickness, and possible warping.

The problems of laser cut woodworking can be properly dealt with by inspecting the wood piece first and ensuring that sufficient ventilation and fire-safety measures are taken, along with the below-mentioned precautions. Let’s get them one by one:

1.Charring and Burn Marks

One of the most common problems during laser cut woodworking is burning and charring on the wood surface. It can happen due to the high power of CO2 laser cutters or the longer exposure of diode laser cutters, which are generally low-powered. The best way to deal with this problem is to have sufficient airflow maintained in the work area to remove the residue. The Ortur Air Pump 1.0 included in the latest laser machines from Ortur boosts up to 50L/min of airflow, which efficiently fixes the issues of charring and burn marks.

2. Limited Cutting Depths

Another common problem during engraving is that most of the common diode laser cutters struggle to cut through thick wooden structures, which results in undesired results. Treatment of wood before starting the cutting or using high-power laser cutters with precise cutting can deal with this problem. Like the OLM3 20W laser cutter, which can easily handle the cutting of 10mm plywood, 15mm pine board, and 8mm black acrylic in only one pass.

3. Inconsistent Cuts

Laser cutting of wood can be inconsistent, which practically means a high level of variability in the quality, depth, and precision of the laser cut. This happens when the laser beam is wrongly focused into the focusing lens, or there may be variations in the grain and density of the material or poor adjustment of the laser cutting parameters.

To produce more consistent results, the laser beam has to be focused, and one has to make a proper selection of materials with consistent properties. The use of jigs and fixtures will help secure both the material and allow more stability in the positioning of the material during the cutting process. New, advanced laser cutters have working areas designed to deal with such situations the Quick Focus Stick available in Ortur LM3 LU3-20A is designed to deal with inconsistent cuts by being as focused as possible.

4. Buildup of Resins and Smoke

Resin buildup in the optics is most common when cutting woods that have a high resin content, such as pine. The high temperature at which the laser operates subjects the resin to heat and instant vaporization. This vapor condenses on the laser optics and covers the laser beam's optics, resulting in altered cutting and engraving. The resin deposits may further transform into hard deposits inside the optics, resulting in further damage.

An air assist system is frequently used to solve this issue because it blows away the smoke and resin vapors during the cutting cycle and assists in overcoming the buildup. Like the one found in Ortur LM3 with a dual fan setup reaching 10,000 rpm and blinds for high and guided airflow. This increases the laser’s lifetime and ensures smooth operation.

5. Kerf Width Variability

The kerf size (the width of the cut) changes with different focusing and power outputs, either expanding or contracting, hence, precision in cutting may be lost. Focusing on each cut and tuning laser parameters with the finer details of each wood type is needed to deal with this problem. If you want to avoid this particular problem, we recommend going for a precise laser printer with CO2 technology like the Ortur LM3 with an accuracy threshold of 0.01mm for a 0.08*0.08mm2 spot. This ensures high precision and smooth operation during cutting and engraving with this machine.

Do Laser Cut Woodworking Like a Pro

And you can do that when you know the use cases of two types of laser cutters available on the market. In general, diode laser cutters are also effective for engraving and cutting on wood surfaces, while CO2 laser cutters are considered most effective for the job, especially when the wood width is greater.

The diode laser cutters are more effective for lighter DIY projects, while the CO2 ones are suitable for projects with thicker wood and when high-quality engravings are needed. For such a scenario, we recommend going for the Ortur LM3 laser machine, which comes with a Quick Focus Stick for precise cutting, a superior air cooling system with guided airflow blinds, and a high power rating suitable for wood cutting. All this makes it suitable for high-resolution engraving and detailed designs on wood surfaces.

Wrapping up

The problems of laser cut woodworking can be easily dealt with by understanding and following the above-stated reasons for such issues. Wood engraving remains one of the most commonly used personalization techniques for home decor and gifts. For DIY projects, it is commonly used for multiple purposes where it offers durability and versatility. Whatever reason you have for using wood with laser cutters, the Ortur LM3 can be a reliable and efficient machine option for you.

Your Essential Guide to Laser Cut Woodworking and Engraving

This article is written to be your best guide to laser cut woodworking and engraving without facing the common issues that most people go through during wood laser cutting.16

- The Problems of Laser Cut Woodworking

- Do Laser Cut Woodworking Like a Pro

- Wrapping up

The Problems of Laser Cut Woodworking

After plastics, wood is the second most used material for DIY projects because of its versatility and wide variety of personal and industrial applications. It can be cut, sanded, shaped, and finished into nearly infinite designs, offering high aesthetic value. Wood can be laser cut for precise engraving, those small signboards and displays at the coffee shops near your house are all laser engraved. This technique is also used in home décor and personalized wooden gifts.

Although wood laser cutting and engraving is great and frequently used, it can also go through common problems such as burning wood, inconsistency in the cuts, potential fire hazards, resin buildup, and even smoke and fumes. This happens due to inconsistent kerf width, material thickness, and possible warping.

The problems of laser cut woodworking can be properly dealt with by inspecting the wood piece first and ensuring that sufficient ventilation and fire-safety measures are taken, along with the below-mentioned precautions. Let’s get them one by one:

1. Charring and Burn Marks

One of the most common problems during laser cut woodworking is burning and charring on the wood surface. It can happen due to the high power of CO2 laser cutters or the longer exposure of diode laser cutters, which are generally low-powered. The best way to deal with this problem is to have sufficient airflow maintained in the work area to remove the residue. The Ortur Air Pump 1.0 included in the latest laser machines from Ortur boosts up to 50L/min of airflow, which efficiently fixes the issues of charring and burn marks.

2. Limited Cutting Depths

Another common problem during engraving is that most of the common diode laser cutters struggle to cut through thick wooden structures, which results in undesired results. Treatment of wood before starting the cutting or using high-power laser cutters with precise cutting can deal with this problem. Like the OLM3 20W laser cutter, which can easily handle the cutting of 10mm plywood, 15mm pine board, and 8mm black acrylic in only one pass.

3. Inconsistent Cuts

Laser cutting of wood can be inconsistent, which practically means a high level of variability in the quality, depth, and precision of the laser cut. This happens when the laser beam is wrongly focused into the focusing lens, or there may be variations in the grain and density of the material or poor adjustment of the laser cutting parameters.

To produce more consistent results, the laser beam has to be focused, and one has to make a proper selection of materials with consistent properties. The use of jigs and fixtures will help secure both the material and allow more stability in the positioning of the material during the cutting process. New, advanced laser cutters have working areas designed to deal with such situations the Quick Focus Stick available in Ortur LM3 LU3-20A is designed to deal with inconsistent cuts by being as focused as possible.

4. Buildup of Resins and Smoke

Resin buildup in the optics is most common when cutting woods that have a high resin content, such as pine. The high temperature at which the laser operates subjects the resin to heat and instant vaporization. This vapor condenses on the laser optics and covers the laser beam's optics, resulting in altered cutting and engraving. The resin deposits may further transform into hard deposits inside the optics, resulting in further damage.

An air assist system is frequently used to solve this issue because it blows away the smoke and resin vapors during the cutting cycle and assists in overcoming the buildup. Like the one found in Ortur LM3 with a dual fan setup reaching 10,000 rpm and blinds for high and guided airflow. This increases the laser’s lifetime and ensures smooth operation.

5. Kerf Width Variability

The kerf size (the width of the cut) changes with different focusing and power outputs, either expanding or contracting, hence, precision in cutting may be lost. Focusing on each cut and tuning laser parameters with the finer details of each wood type is needed to deal with this problem. If you want to avoid this particular problem, we recommend going for a precise laser printer with CO2 technology like the Ortur LM3 with an accuracy threshold of 0.01mm for a 0.08*0.08mm2 spot. This ensures high precision and smooth operation during cutting and engraving with this machine.

Do Laser Cut Woodworking Like a Pro

And you can do that when you know the use cases of two types of laser cutters available on the market. In general, diode laser cutters are also effective for engraving and cutting on wood surfaces, while CO2 laser cutters are considered most effective for the job, especially when the wood width is greater.

The diode laser cutters are more effective for lighter DIY projects, while the CO2 ones are suitable for projects with thicker wood and when high-quality engravings are needed. For such a scenario, we recommend going for the Ortur LM3 laser machine, which comes with a Quick Focus Stick for precise cutting, a superior air cooling system with guided airflow blinds, and a high power rating suitable for wood cutting. All this makes it suitable for high-resolution engraving and detailed designs on wood surfaces.

Wrapping up

The problems of laser cut woodworking can be easily dealt with by understanding and following the above-stated reasons for such issues. Wood engraving remains one of the most commonly used personalization techniques for home decor and gifts. For DIY projects, it is commonly used for multiple purposes where it offers durability and versatility. Whatever reason you have for using wood with laser cutters, the Ortur LM3 can be a reliable and efficient machine option for you.

Keep in Touch with Ortur

Keep in Touch with Ortur

Related Articles

3 Creative Ways to Cut a Shirt with a Laser Cutter

Engraving Time, Creating the Future

Your 2024 Yearly Dose of the Best Laser Engraving Ideas

Related Articles

Engraving Time, Creating the Future